Water Heater

Date: February 2018 & October 2020

Customer: Uniper Energy

Location: Killingholme

Background

Uniper Energy had a large water heater that isn’t currently being used, and so the decision was made to mothball it for approximately two years.

1) The Task

HSL were approached to provide a solution to prevent the water tank and the internal gas path from any further corrosion during the mothballing period.

2) Product Used

-

VpCI 337

-

VpCI 649

3) The Solution

The exhaust stacks, the top and bottom of the filter housings was sealed with MilCorr. The MilCorr was then heat shrunk using a propane powered heat gun

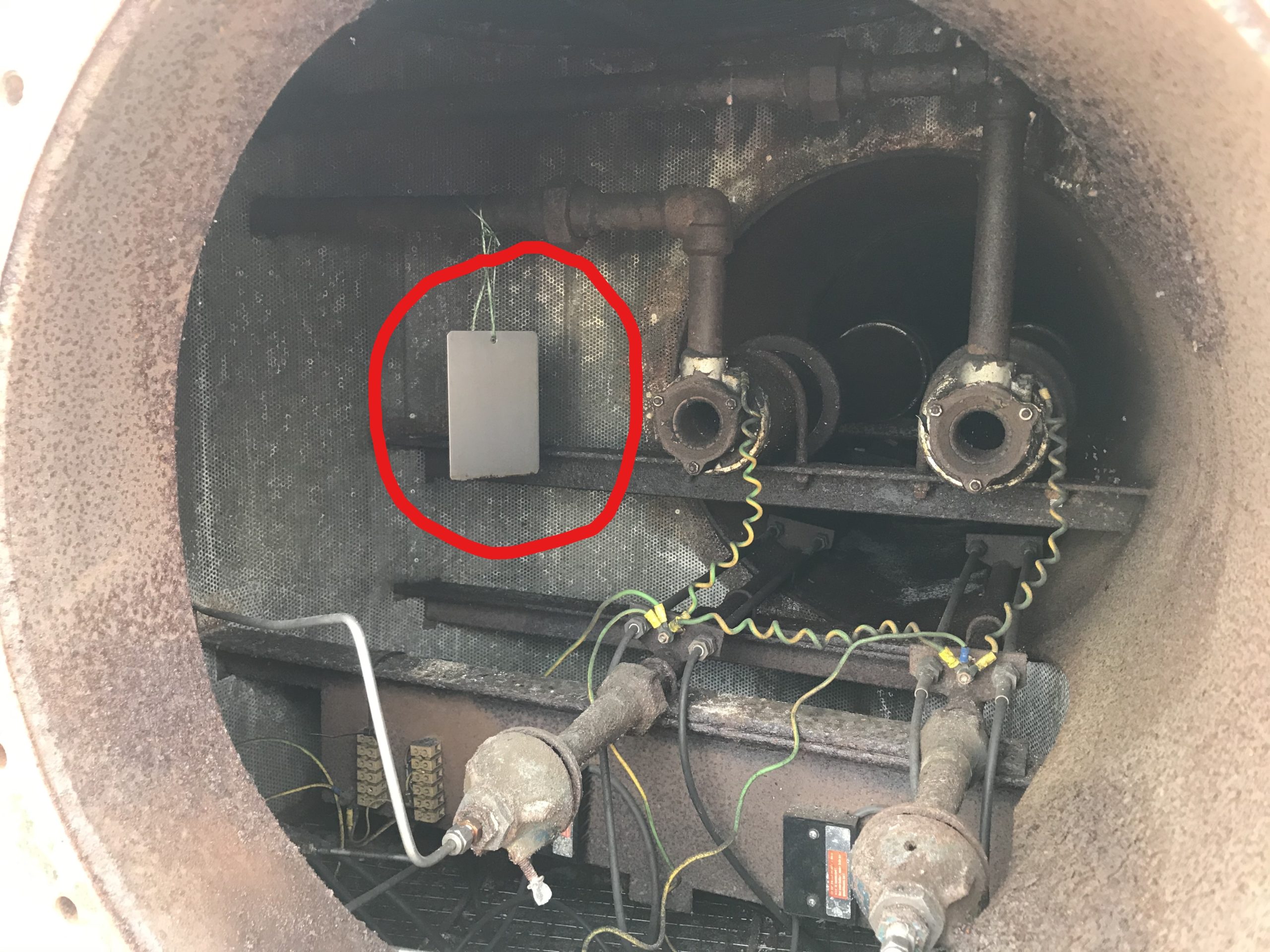

The gas path was treated with VpCI 337 at a rate of 1L/m3 using an airlessco LP 540 sprayer. A low grade carbon steel plate was hung in the gas path as visual evidence that no degradation / corrosion was taking place.

The water tank was being left with a water/glycol mix in it, so VpCI 649 was added at 2%, this was pumped into the tank and then circulated to ensure a good mix.

This treatment has resulted in the low cost storage of this high value asset for up to two years.

Note: In October 2020 (almost 3 years later), Uniper requested the water heater be re-treated, the plate pictured below was taken when the gas path was opened up, proving protection from corrosion had been achieved.