Gas Turbines Preservation

Date: August 2007

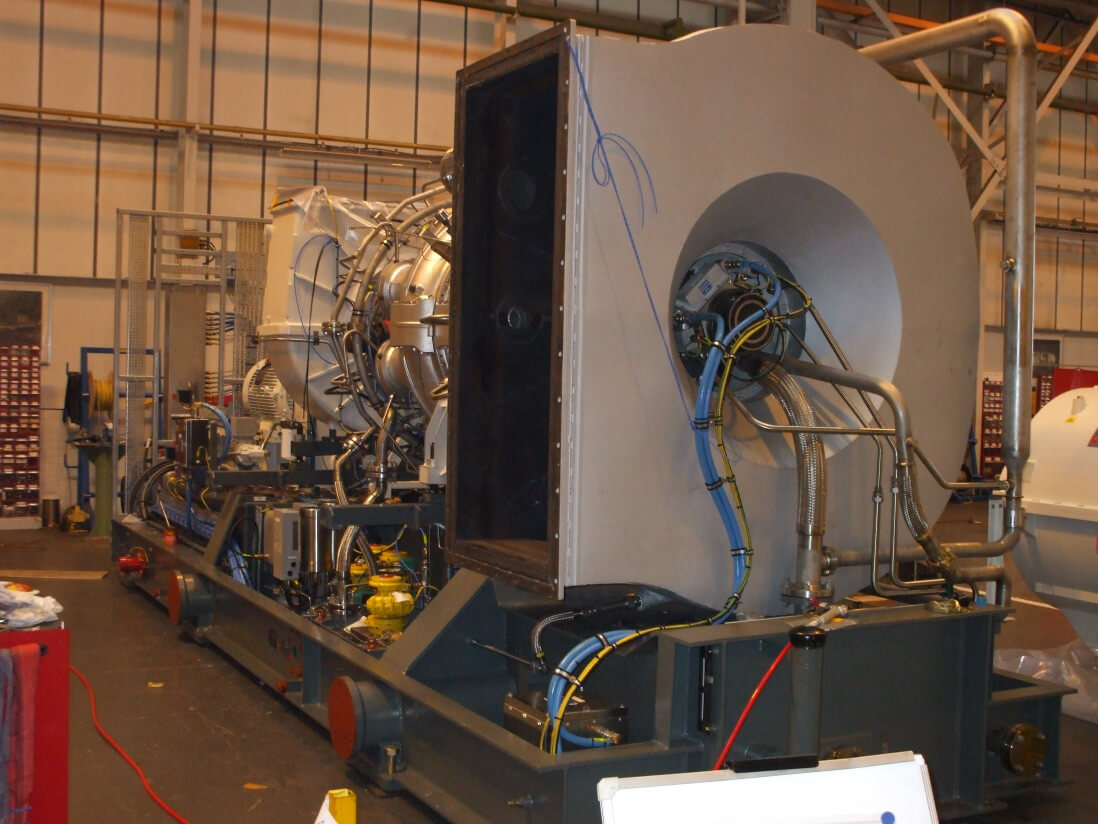

Customer: Siemens

Location: Lincoln, England

Background

Siemens transport Gas Turbines worldwide after they have been built / refurbished at their Lincoln plant. Siemens were experiencing problems with corrosion in the oil sump (transported dry) and the bearings upon arrival at their destination.

1) The Task

HITEK-nology Solutions Ltd was approached by the customer to provide a solution that protected the sump and bearings whilst still allowing the turbines to be transported world wide.

2) Product Used

- VpCI 322

- VpCI 126

- VpCI 132 Foam Pads

3) The Solution

VpCI 322 is fogged into the internal volume of the sump and the bearings resulting in a low cost anti-corrosion protection, whilst both in storage before and during transportation.

HITEK-nology Solutions Ltd has since been requested to treat more gas turbines. We also now protect all the electrical junction boxes with VpCI Emitters and the Unison Rings (gearing System) with VpCI 132 Foam Pads and VpCI 126 Blue.